50 Years Warranty

It has high resistance to aggressive elements that provides longer durability and usage.

Designed for hot & cold piping system

With its physical and chemical properties, it is a versatile piping system that can be used on different industry application.

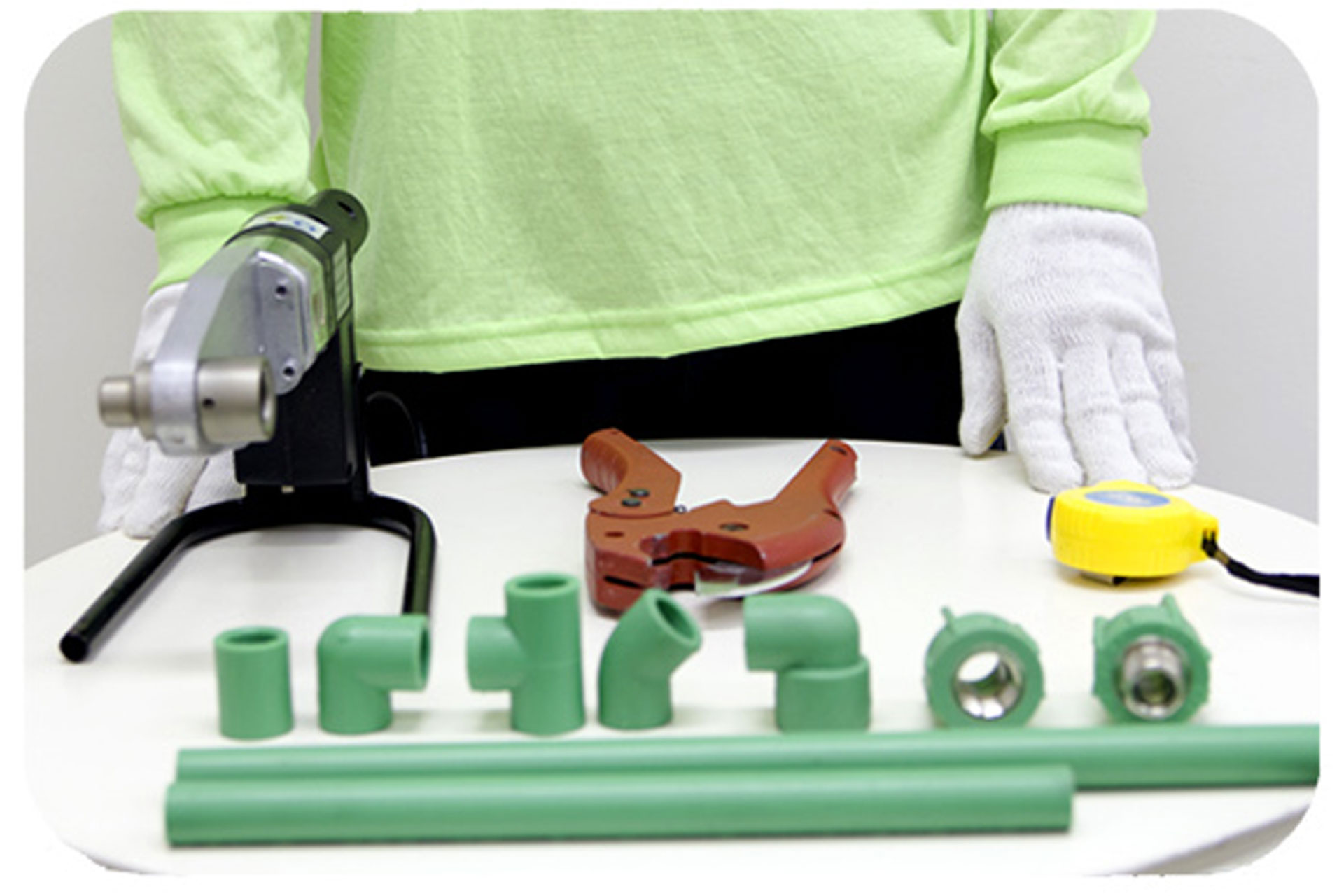

Fusion Technology

Installation of PPR pipes is more practical, easier, quicker and cleaner.

Toxic Free

It is manufactured with non-toxic and physiologically harmless material, to ensure the safety of people on usage.

Cost efficient

With all its characteristics combined resulting to efficiency and durability, it lessens the cost of replacements and maintenance of the piping system.

100% Virgin Raw Material From Korea

It is manufactured from high quality Polypropylene Random Co-polymer resins that gives the advantage of high impact strength and resistance to high temperature.

Applications of PP-R

Central Heating Systems for residential and commercial buildings, hotels and hospitals

Industrial Chemicals and Aggressive Fluids transportation

Chilled Water Networks in Air Conditioning Sytems

Agricultural and Horticultural use (Irrigation)

Swimming Pool pipe networks

HVAC and Compressed Air Installations

Portable Water Supply Systems

Applications of PP-R

Central Heating Systems for residential and commercial buildings, hotels and hospitals

Industrial Chemicals and Aggressive Fluids transportation

Chilled Water Networks in Air Conditioning Sytems

Agricultural and Horticultural use (Irrigation)

Swimming Pool pipe networks

HVAC and Compressed Air Installations

Portable Water Supply Systems

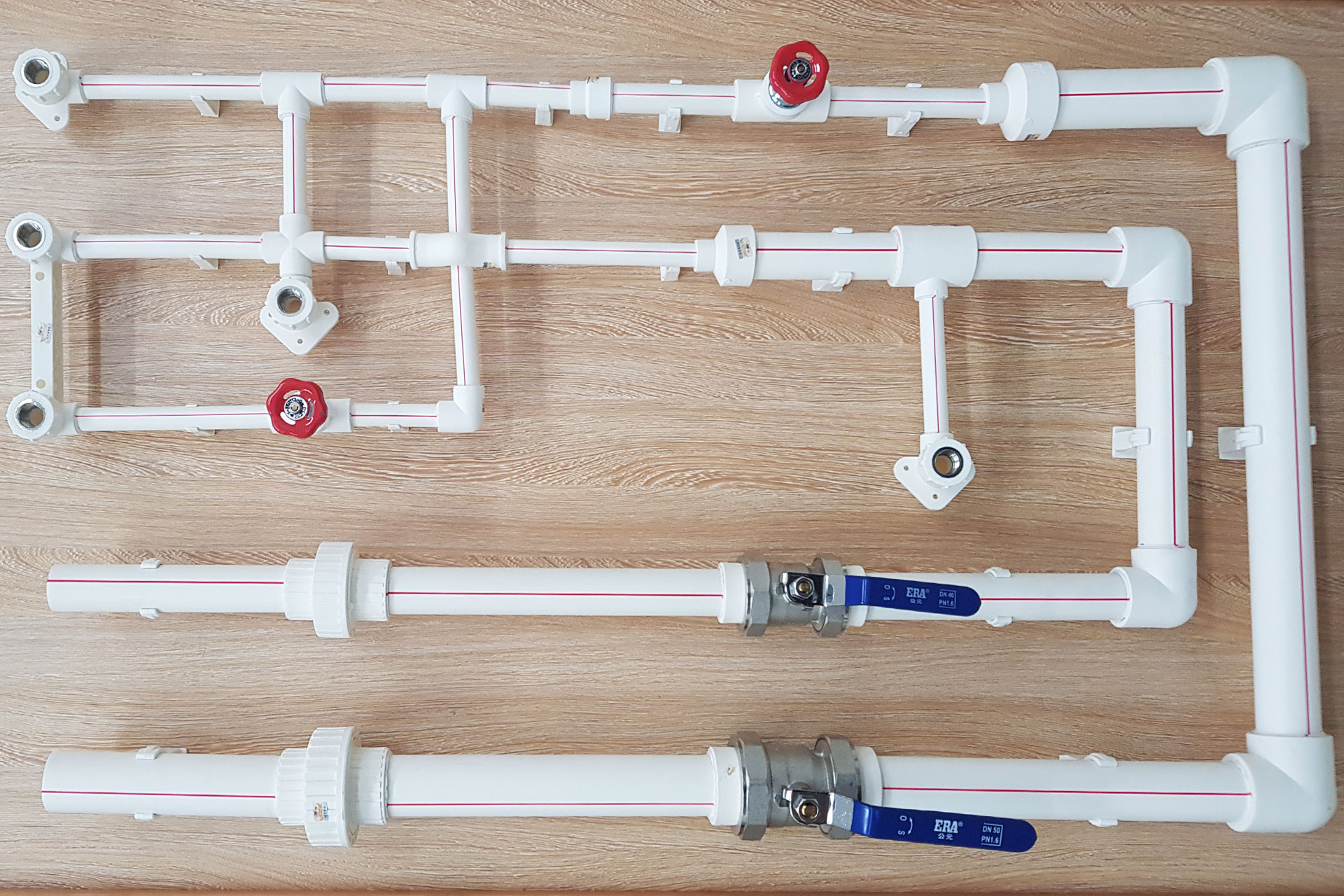

Advantages of using ERA PP-R

Designed & Specified for Hot & Cold potable water applications in hospitals, hotels and food establishments

Safe, Non-toxic and Physiologically Harmless Food Grade material

Rust and Corrossion free

High Pressure Tolerance rating

Heat preservation and energy-saving abilities

High acoustic insulation against fluid noise

Lightweight and Easy to Transport

With Heat Fusion Technology pipe installation is more practical and easy ensuring Leak Free connections

High resistance to aggressive elements giving the system an extremely long service life of 50 years and more

50 Year Warranty on leaks

Easy connectivity over a complex network

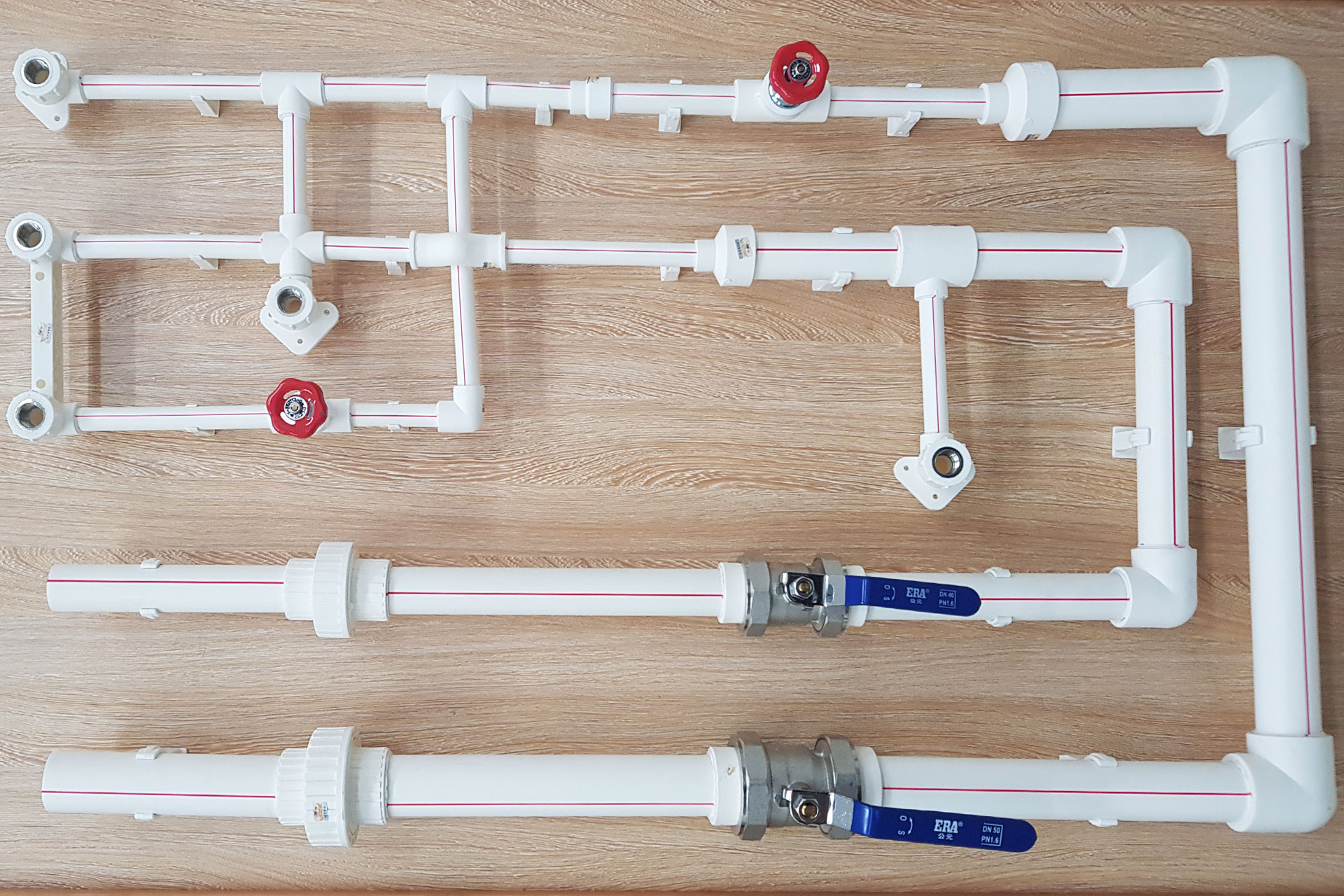

Certificate of High Standards

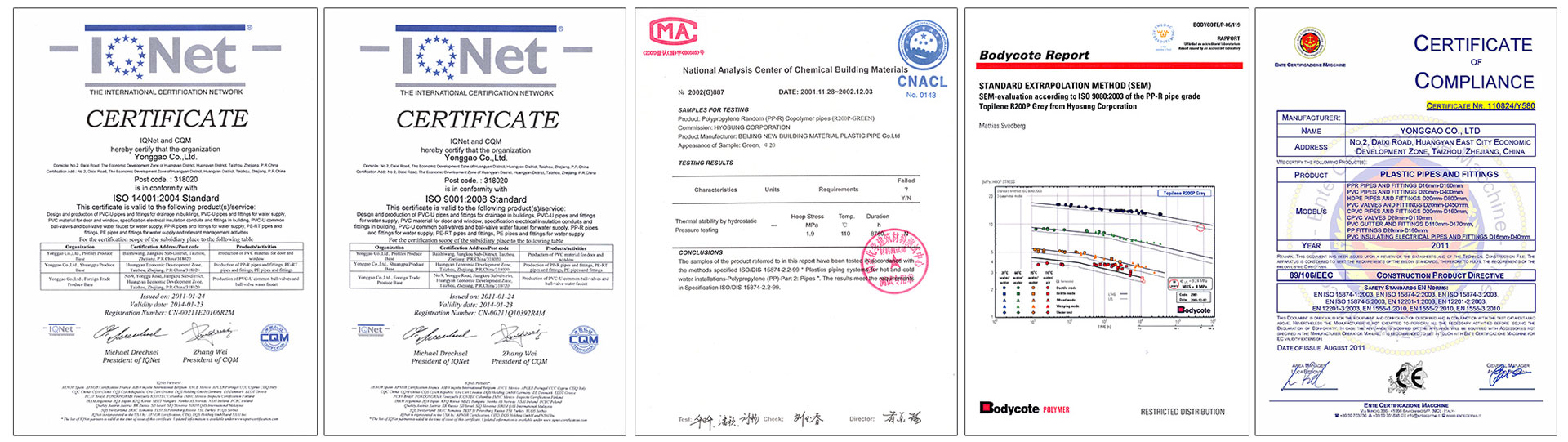

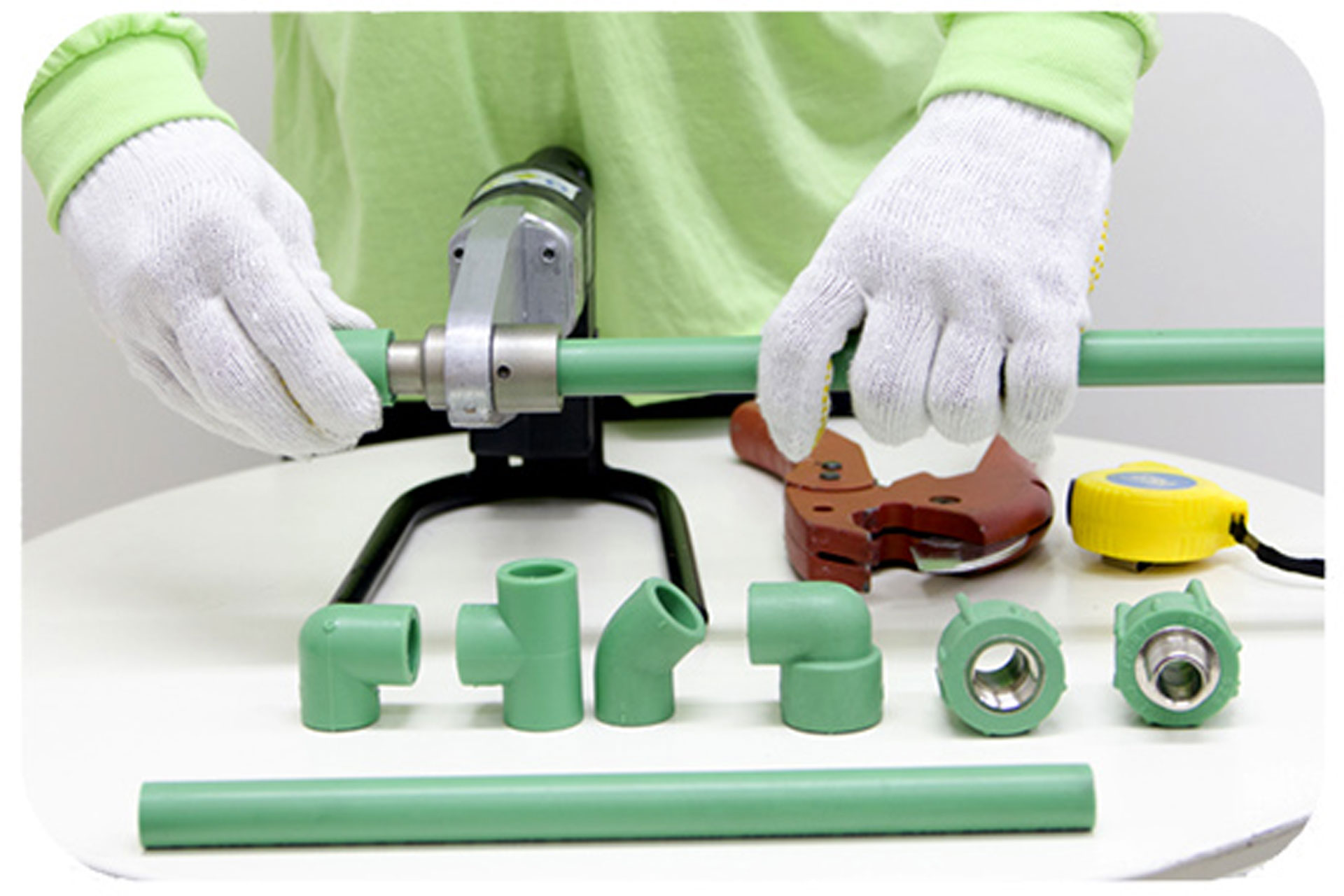

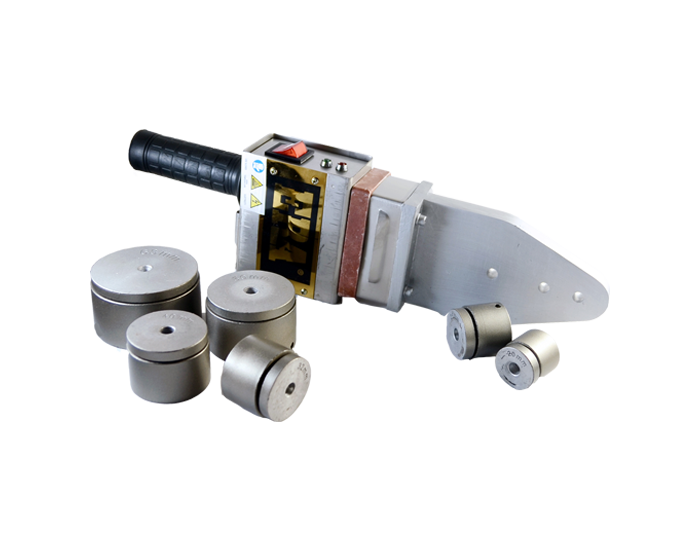

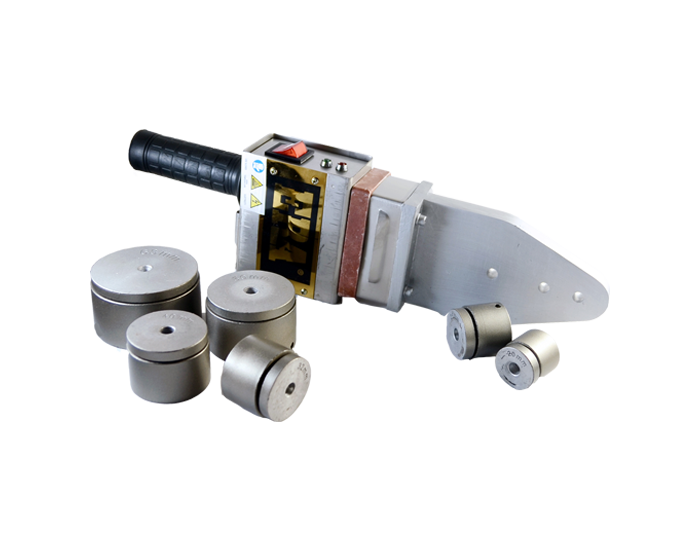

Installation of ERA PP-R Pipes

1. Make sure that the welding tools (FusionMachine), pipes and fittings to be fused are clean.

2. Mark and cut the length of the pipe to be fused with the pipe scissor perpendicular to its axis. Have the fittings ready and within easy reach.

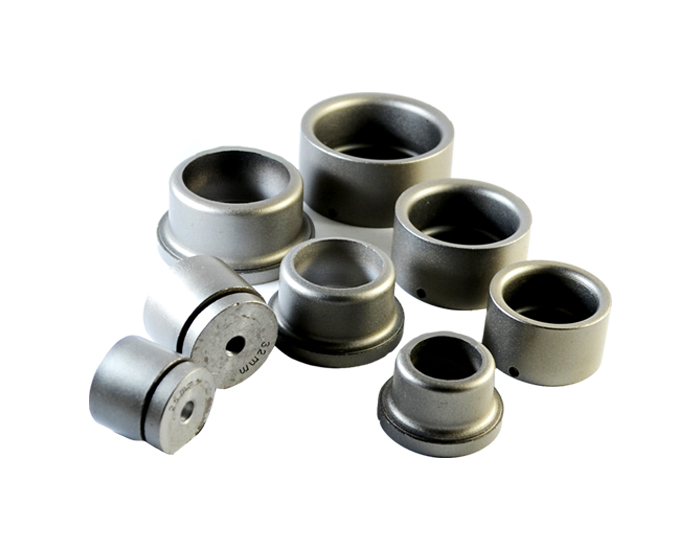

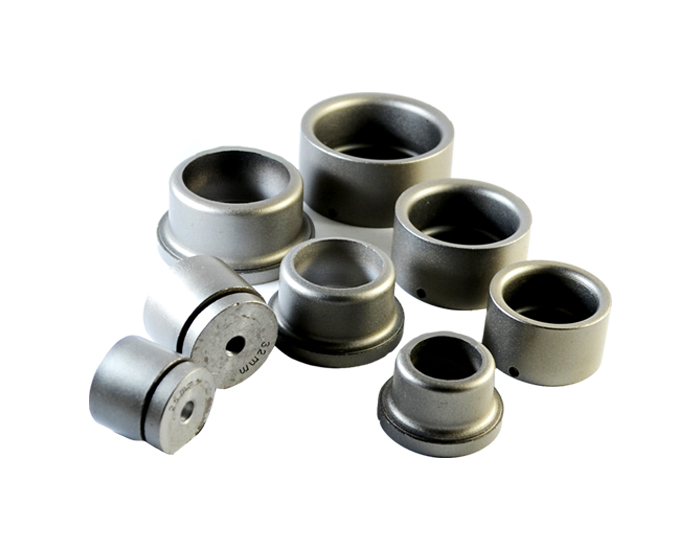

Attach and tighten the Fusion Sleeves (Special Welding Tool) to the heating element of the machine with the Hex Key.

Plug the fusion machine to an electrical outlet (you will see a red bulb light up). The machine will be warmed up to 260 degrees Centigrade when the red light goes off and when the green light goes on.

2. Mark and cut the length of the pipe to be fused with the pipe scissor perpendicular to its axis. Have the fittings ready and within easy reach.

Attach and tighten the Fusion Sleeves (Special Welding Tool) to the heating element of the machine with the Hex Key.

Plug the fusion machine to an electrical outlet (you will see a red bulb light up). The machine will be warmed up to 260 degrees Centigrade when the red light goes off and when the green light goes on.

3. Push the pipe and fitting towards the sleeves of the Special Welding Tool.

When you hear a sound and see some material come out of the small hole at the end of the Special Welding Tool, you may pull out the pipe and the fitting.

4. Without losing time, fuse the pipe and the fitting firmly. Do not twist the pipe and fitting while fusing. In just few seconds, you already have a leak-free, long life and tight joint.

4. Without losing time, fuse the pipe and the fitting firmly. Do not twist the pipe and fitting while fusing. In just few seconds, you already have a leak-free, long life and tight joint.

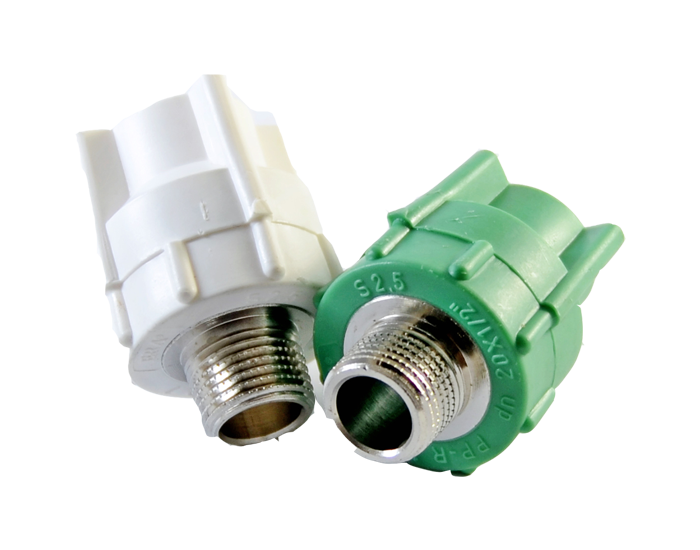

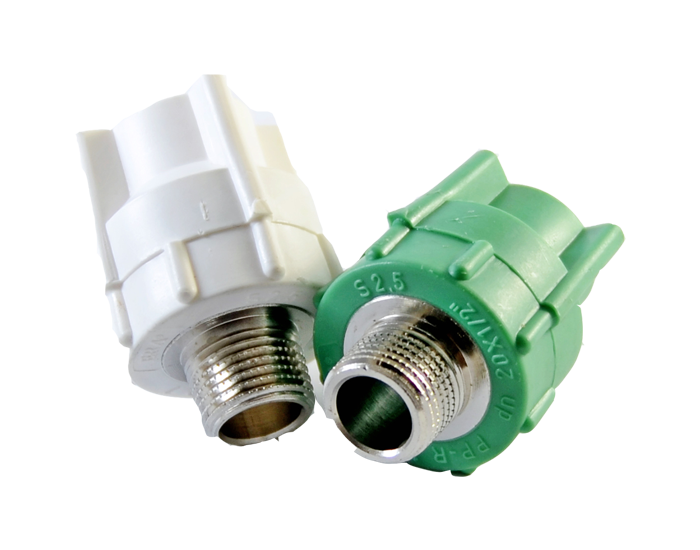

Why choose ERA PP-R?

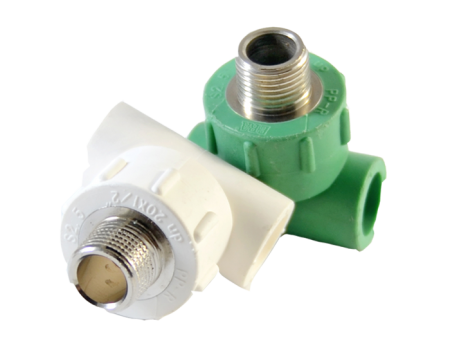

ERA PP-R Pipes & Fittings undergo the ERA Quality Process. ERA Quality Action Teams throughout the world work continually to improve our products to meet customer requirements and expectations. The pictures below shows a glaring comparison of an ERA PP-R male adapter with thread and those of Brand X and Brand Y in terms of their weight and cross-section view.

Why choose ERA PP-R?

ERA PP-R Pipes & Fittings undergo the ERA Quality Process. ERA Quality Action Teams throughout the world work continually to improve our products to meet customer requirements and expectations. The pictures below shows a glaring comparison of an ERA PP-R male adapter with thread and those of Brand X and Brand Y in terms of their weight and cross-section view.

Weight Comparison

Thread Comparison

Try our ERA PPR High Pressure Piping System!

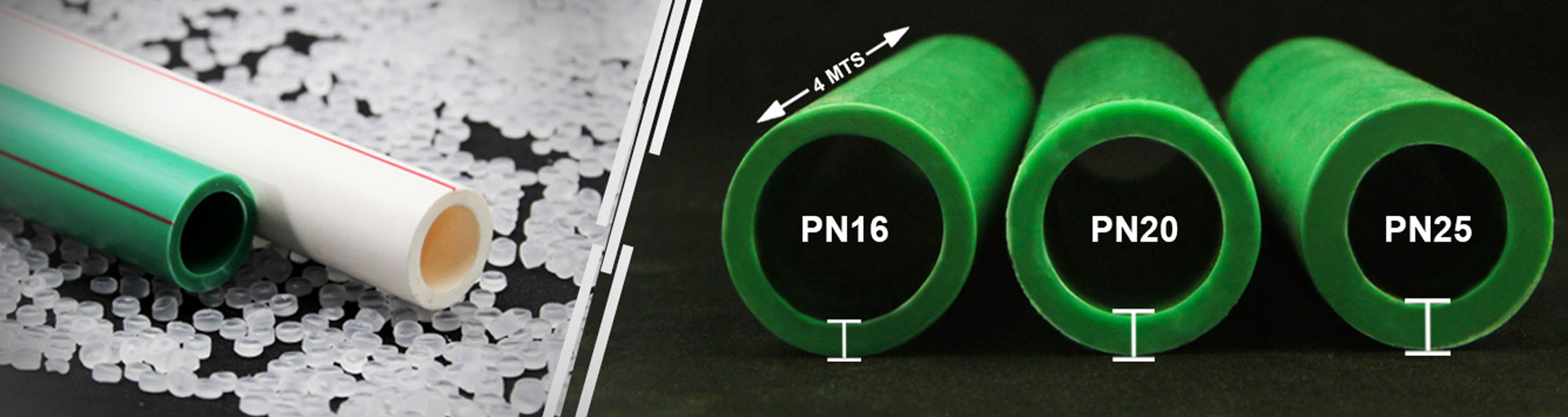

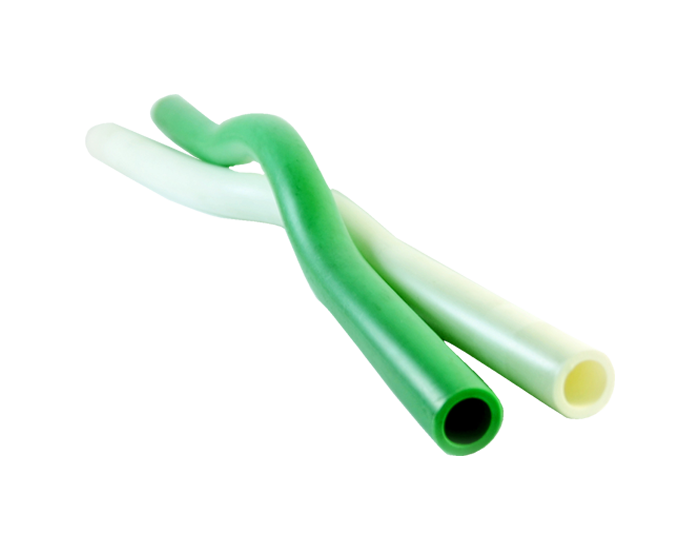

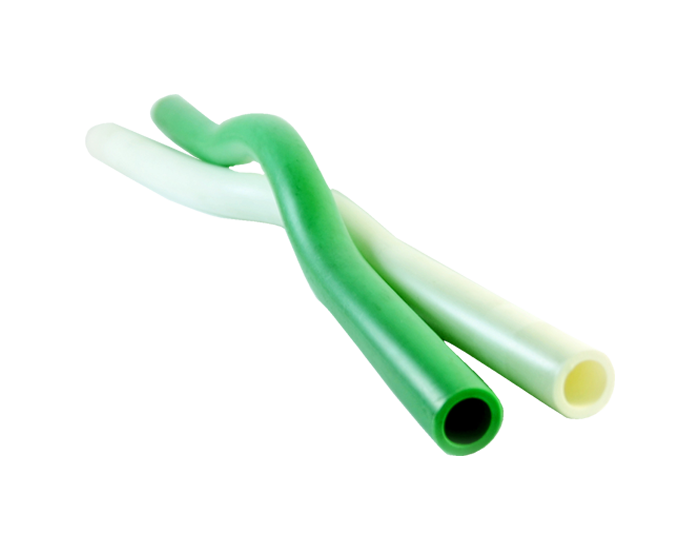

PPR Hot & Cold Pipes

PN16 (FOR COLD WATER - POTABLE)

Dimension

-

- 20

- 25

- 32

- 40

- 50

- 63

- 75

- 90

- 110

Diameter

-

- 20 mm

- 25 mm

- 32 mm

- 40 mm

- 50 mm

- 63 mm

- 75 mm

- 90 mm

- 110 mm

Wall Thickness

-

- 2.3 mm

- 2.8 mm

- 3.6 mm

- 4.5 mm

- 5.6 mm

- 7.1 mm

- 8.4 mm

- 10.1 mm

- 12.3 mm

Internal Diameter

-

- 15.4 mm

- 19.4 mm

- 24.8 mm

- 31.0 mm

- 38.8 mm

- 48.8 mm

- 61.4 mm

- 73.6 mm

- 90.0 mm

Weight

-

- 0.50 Kg/m

- 0.76 Kg/m

- 1.23 Kg/m

- 1.90 Kg/m

- 2.49 Kg/m

- 4.82 Kg/m

- 6.66 Kg/m

- 9.53 Kg/m

- 14.31 Kg/m

PN20 (FOR HOT & COLD - POTABLE)

Dimension

-

- 20

- 25

- 32

- 40

- 50

- 63

- 75

- 90

- 110

Diameter

-

- 20 mm

- 25 mm

- 32 mm

- 40 mm

- 50 mm

- 63 mm

- 75 mm

- 90 mm

- 110 mm

Wall Thickness

-

- 2.8 mm

- 3.5 mm

- 4.4 mm

- 5.5 mm

- 6.9 mm

- 8.7 mm

- 10.3 mm

- 12.3 mm

- 15.1 mm

Internal Diameter

-

- 14.4 mm

- 18.0 mm

- 23.2 mm

- 29.0 mm

- 36.2 mm

- 45.8 mm

- 54.4 mm

- 65.4 mm

- 79.8 mm

Weight

-

- 0.58 Kg/m

- 0.90 Kg/m

- 1.44 Kg/m

- 2.20 Kg/m

- 3.48 Kg/m

- 5.44 Kg/m

- 7.87 Kg/m

- 11.28 Kg/m

- 17.09 Kg/m

PN25 (FOR HOT & COLD - POTABLE)

Dimension

-

- 20

- 25

- 32

- 40

- 50

- 63

- 75

- 90

- 110

Diameter

-

- 20 mm

- 25 mm

- 32 mm

- 40 mm

- 50 mm

- 63 mm

- 75 mm

- 90 mm

- 110 mm

Wall Thickness

-

- 3.4 mm

- 4.2 mm

- 5.4 mm

- 6.7 mm

- 8.4 mm

- 10.5 mm

- 12.5 mm

- 15.0 mm

- 18.3 mm

Internal Diameter

-

- 13.2 mm

- 16.6 mm

- 21.2 mm

- 26.6 mm

- 33.4 mm

- 42.0 mm

- 61.4 mm

- 73.6 mm

- 90.0 mm

Weight

-

- 0.68 Kg/m

- 1.04 Kg/m

- 1.70 Kg/m

- 2.61 Kg/m

- 4.07 Kg/m

- 6.42 Kg/m

- 9.09 Kg/m

- 13.05 Kg/m

- 19.20 Kg/m

PPR Hot & Cold Fittings

ELBOW 90° DEG

Sizes

-

- EE90 20 mm

- EE90 25 mm

- EE90 32 mm

- EE90 40mm

- EE90 50mm

- EE90 63 mm

- EE90 75 mm

- EE90 90 mm

- EE90 110 mm

ELBOW 45° DEG

Sizes

-

- EE45 20 mm

- EE45 25 mm

- EE45 32 mm

- EE45 40mm

- EE45 50mm

- EE45 63 mm

- EE45 75 mm

- EE45 90 mm

- EE45 110 mm

ELBOW 90° DEG

Sizes

-

- EE90 20 mm

- EE90 25 mm

- EE90 32 mm

- EE90 40mm

- EE90 50mm

- EE90 63 mm

- EE90 75 mm

- EE90 90 mm

- EE90 110 mm

ELBOW 45° DEG

Sizes

-

- EE45 20 mm

- EE45 25 mm

- EE45 32 mm

- EE45 40mm

- EE45 50mm

- EE45 63 mm

- EE45 75 mm

- EE45 90 mm

- EE45 110 mm

ELBOW REDUCER

Sizes

-

- EER 25 mm x 20 mm

- EER 32 mm x 25 mm

- EER 32 mm x 20 mm

COUPLING

Sizes

-

- EC 20 mm

- EC5 25 mm

- EC 32 mm

- EC 40mm

- EC 50mm

- EC 63 mm

- EC 75 mm

- EC 90 mm

- EC 110 mm

ELBOW REDUCER

Sizes

-

- EER 25 mm x 20 mm

- EER 32 mm x 25 mm

- EER 32 mm x 20 mm

COUPLING

Sizes

-

- EE45 20 mm

- EE45 25 mm

- EE45 32 mm

- EE45 40mm

- EE45 50mm

- EE45 63 mm

- EE45 75 mm

- EE45 90 mm

- EE45 110 mm

TEE

Sizes

-

- ET 20 mm

- ET 25 mm

- ET 32 mm

- ET 40mm

- ET 50mm

- ET 63 mm

- ET 75 mm

- ET 90 mm

- ET 110 mm

CAP

Sizes

-

- ECA 20 mm

- ECA 25 mm

- ECA 32 mm

- ECA 40mm

- ECA 50mm

- ECA 63 mm

- ECA 75 mm

- ECA 90 mm

- ECA 110 mm

TEE

Sizes

-

- ET 20 mm

- ET 25 mm

- ET 32 mm

- ET 40mm

- ET 50mm

- ET 63 mm

- ET 75 mm

- ET 90 mm

- ET 110 mm

CAP

Sizes

-

- ECA 20 mm

- ECA 25 mm

- ECA 32 mm

- ECA 40mm

- ECA 50mm

- ECA 63 mm

- ECA 75 mm

- ECA 90 mm

- ECA 110 mm

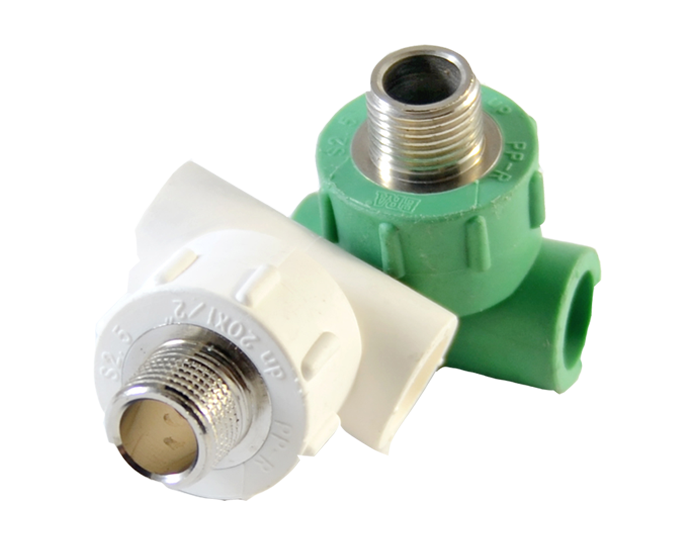

FEMALE ADAPTER W/ BRASS THREAD

Sizes

-

- EFA 20 mm

- EFA 25 mm

- EFA 32 mm

- EFA 40mm

- EFA 50mm

- EFA 63 mm

- EFA 75 mm

- EFA 90 mm

- EFA 110 mm

MALE ADAPTER W/ BRASS THREAD

Sizes

-

- EMA 20 mm

- EMA 25 mm

- EMA 32 mm

- EMA 40mm

- EMA 50mm

- EMA 63 mm

- EMA 75 mm

- EMA 90 mm

- EMA 110 mm

FEMALE ADAPTER W/ BRASS THREAD

Sizes

-

- EFA 20 mm

- EFA 25 mm

- EFA 32 mm

- EFA 40mm

- EFA 50mm

- EFA 63 mm

- EFA 75 mm

- EFA 90 mm

- EFA 110 mm

MALE ADAPTER W/ BRASS THREAD

Sizes

-

- EMA 20 mm

- EMA 25 mm

- EMA 32 mm

- EMA 40mm

- EMA 50mm

- EMA 63 mm

- EMA 75 mm

- EMA 90 mm

- EMA 110 mm

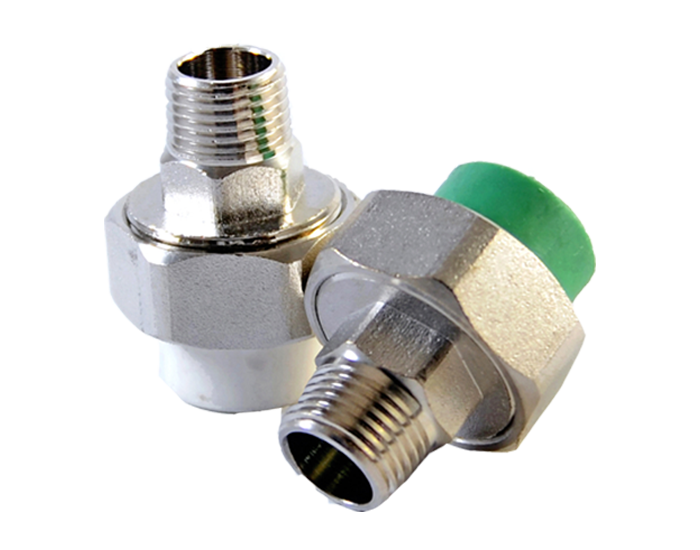

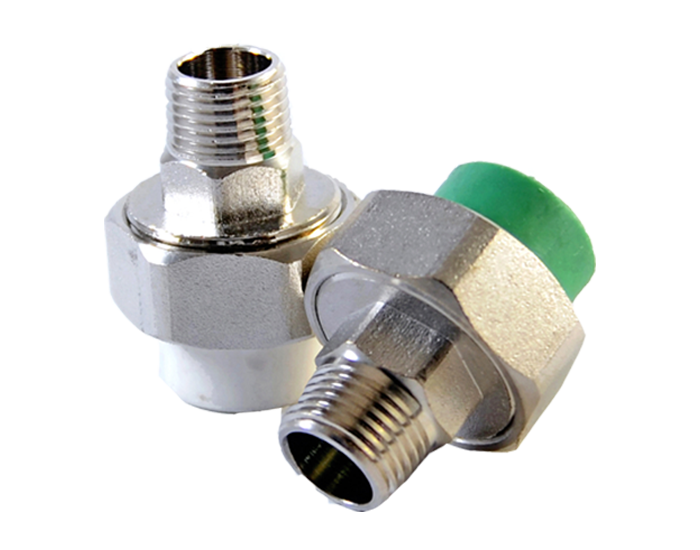

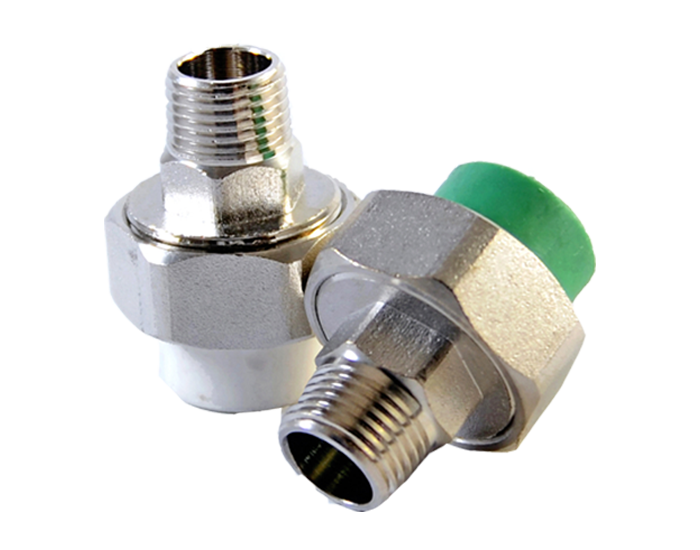

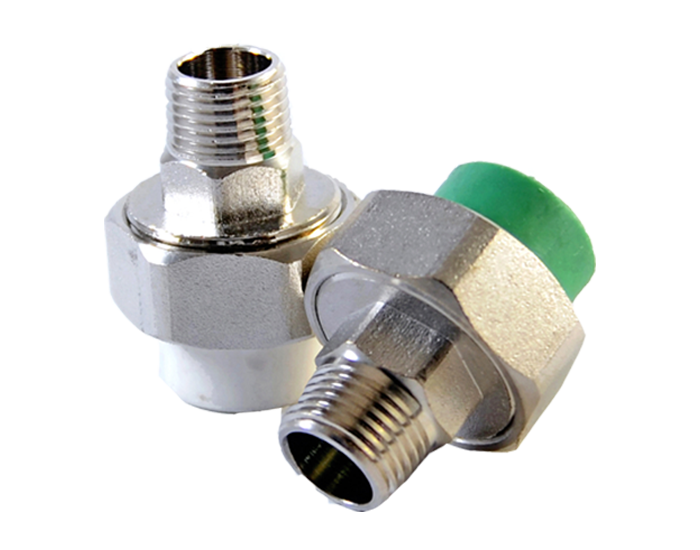

FEMALE UNION W/ BRASS THREAD

Sizes

-

- EFU 20 mm x ½“

- EFU 25 mm x ¾”

- EFU 32 mm x 1”

- EFU 40 mm x 1 ¼”

- EFU 50 mm x 1 ½”

- EFU 63 mm x 2”

- EFU 90 mm x 3”

MALE UNION W/ BRASS THREAD

Sizes

-

- EMU 20 mm x ½“

- EMU 25 mm x ¾”

- EMU 32 mm x 1”

- EMU 40 mm x 1 ¼”

- EMU 50 mm x 1 ½”

- EMU 63 mm x 2”

- EMU 90 mm x 3”

FEMALE UNION W/ BRASS THREAD

Sizes

-

- EFU 20 mm x ½“

- EFU 25 mm x ¾”

- EFU 32 mm x 1”

- EFU 40 mm x 1 ¼”

- EFU 50 mm x 1 ½”

- EFU 63 mm x 2”

- EFU 90 mm x 3”

MALE UNION W/ BRASS THREAD

Sizes

-

- EMU 20 mm x ½“

- EMU 25 mm x ¾”

- EMU 32 mm x 1”

- EMU 40 mm x 1 ¼”

- EMU 50 mm x 1 ½”

- EMU 63 mm x 2”

- EMU 90 mm x 3”

FEMALE TEE W/ BRASS THREAD

Sizes

-

- EFT 20 mm x ½”

- EFT 25 mm x ½”

- EFT 25 mm x 3/4

- EFT 32 mm x ½”

- EFT 32 mm x ¾”

- EFT 32 mm x 1”

MALE TEE W/ BRASS THREAD

Sizes

-

- EMT 20 mm x ½“

- EMT 25 mm x ¾”

- EMT 32 mm x 1”

FEMALE TEE W/ BRASS THREAD

Sizes

-

- EFT 20 mm x ½”

- EFT 25 mm x ½”

- EFT 25 mm x 3/4

- EFT 32 mm x ½”

- EFT 32 mm x ¾”

- EFT 32 mm x 1”

MALE TEE W/ BRASS THREAD

Sizes

-

- EMT 20 mm x ½“

- EMT 25 mm x ¾”

- EMT 32 mm x 1”

FEMALE ELBOW W/ BRASS THREAD

Sizes

-

- EFE 20 mm x ½”

- EFE 25 mm x ½”

- EFE 25 mm x ¾”

- EFE 32 mm x ½”

- EFE 32 mm x ¾”

- EFE 32 mm x 1”

MALE ELBOW W/ BRASS THREAD

Sizes

-

- EME 20 mm x ½“

- EME 25 mm x ¾”

- EME 32 mm x 1”

FEMALE ELBOW W/ BRASS THREAD

Sizes

-

- EFE 20 mm x ½”

- EFE 25 mm x ½”

- EFE 25 mm x ¾”

- EFE 32 mm x ½”

- EFE 32 mm x ¾”

- EFE 32 mm x 1”

MALE ELBOW W/ BRASS THREAD

Sizes

-

- EME 20 mm x ½“

- EME 25 mm x ¾”

- EME 32 mm x 1”

FUSING JOINT

Sizes

-

- EFJ 20 mm

- EFJ 25 mm

- EFJ 32 mm

- EFJ 40mm

- EFJ 50mm

- EFJ 63 mm

- EFJ 75 mm

- EFJ 90 mm

- EFJ 90 mm

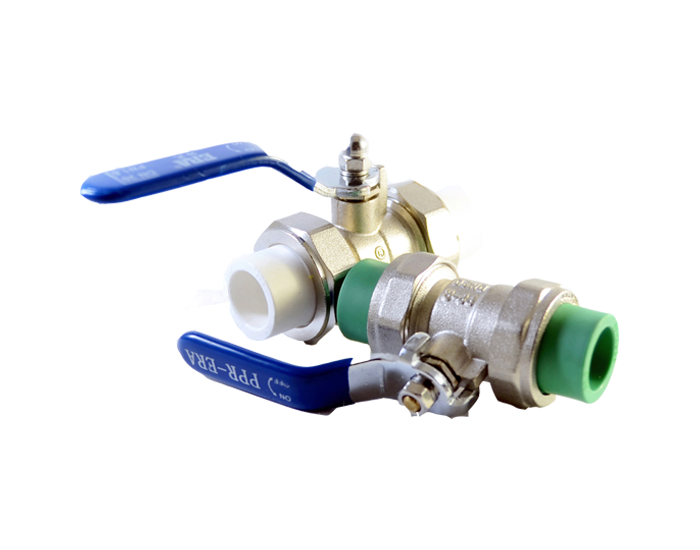

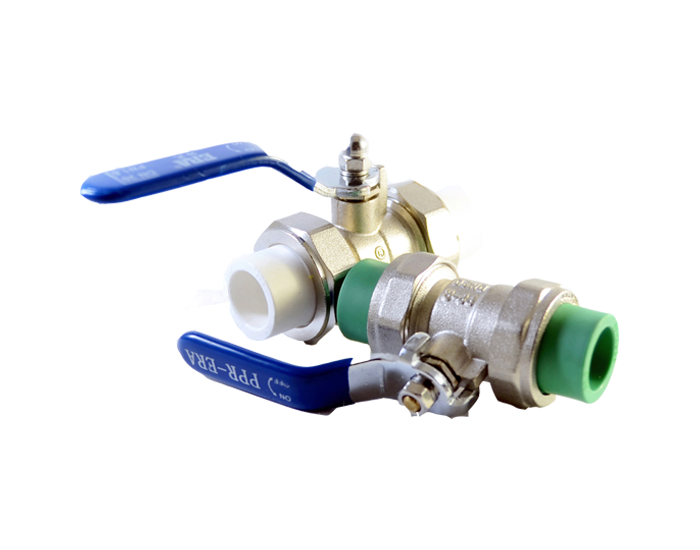

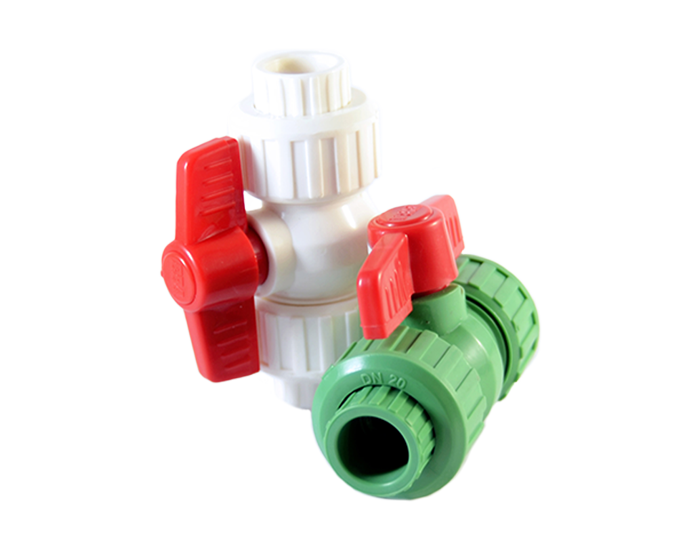

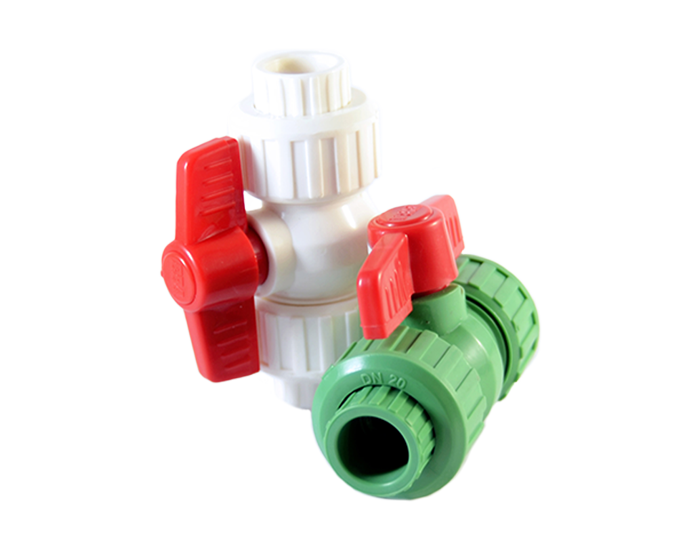

TRUE UNION BALL VALVE

Sizes

-

- ETU 20 mm

- ETU 25 mm

- ETU 32 mm

- ETU 40mm

- ETU 50mm

- ETU 63 mm

FUSING JOINT

Sizes

-

- EFJ 20 mm

- EFJ 25 mm

- EFJ 32 mm

- EFJ 40mm

- EFJ 50mm

- EFJ 63 mm

- EFJ 75 mm

- EFJ 90 mm

- EFJ 90 mm

TRUE UNION BALL VALVE

Sizes

-

- ETU 20 mm

- ETU 25 mm

- ETU 32 mm

- ETU 40mm

- ETU 50mm

- ETU 63 mm

UNION

Sizes

-

- EU 20 mm

- EU 25 mm

- EU 32 mm

- EU 40mm

- EU 50mm

- EU 63 mm

PPR CLIP

Sizes

-

- EPCL 20 mm

- EPCL 25 mm

- EPCL 32 mm

- EPCL 40mm

- EPCL 50mm

- EPCL 63 mm

UNION

Sizes

-

- EU 20 mm

- EU 25 mm

- EU 32 mm

- EU 40mm

- EU 50mm

- EU 63 mm

PPR CLIP

Sizes

-

- EPCL 20 mm

- EPCL 25 mm

- EPCL 32 mm

- EPCL 40mm

- EPCL 50mm

- EPCL 63 mm

SHOWER VALVE

Sizes

-

- ESV 20 mm

- ESV 20 mm

- ESV 32 mm

PPR BRIDGE

Sizes

-

- EPB 20 mm

- EPB 25 mm

- EPB 32 mm

SHOWER VALVE

Sizes

-

- ESV 20 mm

- ESV 20 mm

- ESV 32 mm

PPR BRIDGE

Sizes

-

- EPB 20 mm

- EPB 25 mm

- EPB 32 mm

FEMALE ELBOW W/ WALL PLATE

Sizes

-

- EWP 20 mm x ½“

- EWP 25 mm x ½“

- EWP 25 mm x ¾”

MALE THREADED PLUG

Sizes

-

- EMPT 20 mm

- EMPT 25 mm

- EMPT 32 mm

FEMALE ELBOW W/ WALL PLATE

Sizes

-

- EWP 20 mm x ½“

- EWP 25 mm x ½“

- EWP 25 mm x ¾”

MALE THREADED PLUG

Sizes

-

- EMPT 20 mm

- EMPT 25 mm

- EMPT 32 mm

PPR FLANGE SET

Sizes

-

- EPF 40mm

- EPF 50mm

- EPF 63 mm

- EPF 75 mm

- EPF 90 mm

- EPF 110 mm

STEP OVER BEND

Sizes

-

- ESO 20 mm

- ESO 25 mm

- ESO 32 mm

PPR FLANGE SET

Sizes

-

- EPF 40mm

- EPF 50mm

- EPF 63 mm

- EPF 75 mm

- EPF 90 mm

- EPF 110 mm

STEP OVER BEND

Sizes

-

- ESO 20 mm

- ESO 25 mm

- ESO 32 mm

PPR HEAT FUSING MACHINE

Sizes

-

- EFM 20 to 32

- EFM 20 to 63

- EFM 75 to 110

PPR BALL VALVE

Sizes

-

- EBV 20 mm

- EBV 25 mm

- EBV 32 mm

- EBV 40mm

- EBV 50mm

- EBV 63 mm

PPR HEAT FUSING MACHINE

Sizes

-

- EFM 20 to 32

- EFM 20 to 63

- EFM 75 to 110

PPR BALL VALVE

Sizes

-

- EBV 20 mm

- EBV 25 mm

- EBV 32 mm

- EBV 40mm

- EBV 50mm

- EBV 63 mm

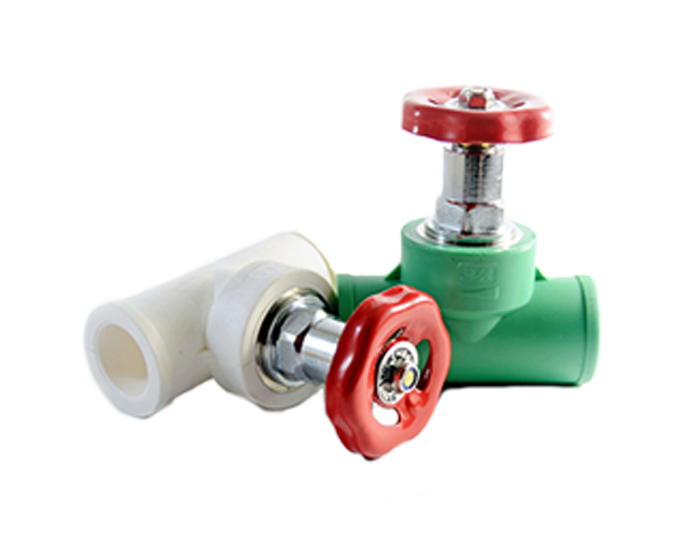

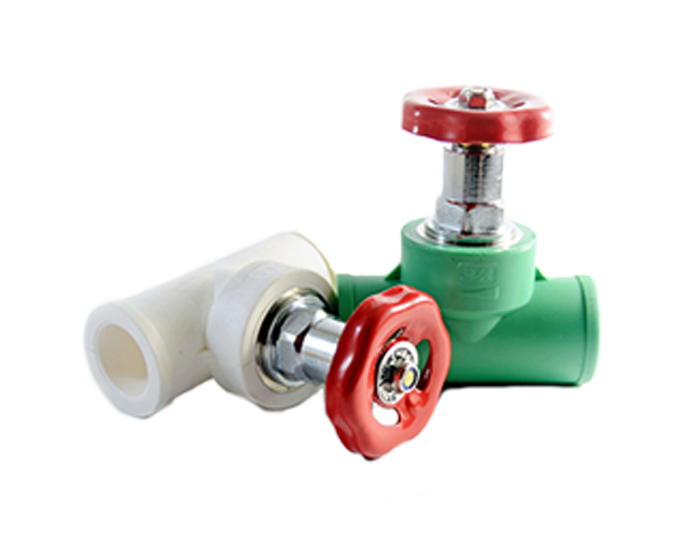

GATE VALVE THREADED

Sizes

-

- EGV 20 mm

- EGV 25 mm

- EGV 32 mm

GATE VALVE PLAIN

Sizes

-

- EGV 20 mm

- EGV 25 mm

- EGV 32 mm

- EGV 40 mm

- EGV 50 mm

- EGV 63 mm

- EGV 75 mm

- EGV 90 mm

- EGV 110 mm

GATE VALVE THREADED

Sizes

-

- EGV 20 mm

- EGV 25 mm

- EGV 32 mm

GATE VALVE PLAIN

Sizes

-

- EGV 20 mm

- EGV 25 mm

- EGV 32 mm

- EGV 40 mm

- EGV 50 mm

- EGV 63 mm

- EGV 75 mm

- EGV 90 mm

- EGV 110 mm

REDUCER

Sizes

-

- ER 25 mm x 20 mm

- ER 32 mm x 20 mm

- ER 32 mm x 25 mm

- ER 40 mm x 20 mm

- ER 40 mm x 25 mm

- ER 40 mm x 32 mm

- ER 50 mm x 20 mm

- ER 50 mm x 25 mm

- ER 50 mm x 32 mm

- ER 50 mm x 40 mm

- ER 63 mm x 25 mm

- ER 63 mm x 32 mm

- ER 63 mm x 40 mm

- ER 63 mm x 50 mm

- ER 75 mm x 40 mm

- ER 75 mm x 50 mm

- ER 75 mm x 63 mm

- ER 90 mm x 50 mm

- ER 90 mm x 63 mm

- ER 90 mm x 75 mm

- ER 110 mm x 63 mm

- ER 110 mm x 75 mm

- ER 110 mm x 90 mm

TEE REDUCER

Sizes

-

- ETR 25 mm x 20 mm

- ETR 32 mm x 20 mm

- ETR 32 mm x 25 mm

- ETR 40 mm x 20 mm

- ETR 40 mm x 25 mm

- ETR 40 mm x 32 mm

- ETR 50 mm x 20 mm

- ETR 50 mm x 25 mm

- ETR 50 mm x 32 mm

- ETR 50 mm x 40 mm

- ETR 63 mm x 20 mm

- ETR 63 mm x 25 mm

- ETR 63 mm x 32 mm

- ETR 63 mm x 40 mm

- ETR 63 mm x 50 mm

- ETR 75 mm x 32 mm

- ETR 75 mm x 40 mm

- ETR 75 mm x 50 mm

- ETR 75 mm x 63 mm

- ETR 90 mm x 40 mm

- ETR 90 mm x 50 mm

- ETR 90 mm x 63 mm

- ETR 90 mm x 75 mm

- ETR 110 mm x 50 mm

- ETR 110 mm x 63 mm

- ETR 110 mm x 75 mm

REDUCER

Sizes

-

- ER 25 mm x 20 mm

- ER 32 mm x 20 mm

- ER 32 mm x 25 mm

- ER 40 mm x 20 mm

- ER 40 mm x 25 mm

- ER 40 mm x 32 mm

- ER 50 mm x 20 mm

- ER 50 mm x 25 mm

- ER 50 mm x 32 mm

- ER 50 mm x 40 mm

- ER 63 mm x 25 mm

- ER 63 mm x 32 mm

- ER 63 mm x 40 mm

- ER 63 mm x 50 mm

- ER 75 mm x 40 mm

- ER 75 mm x 50 mm

- ER 75 mm x 63 mm

- ER 90 mm x 50 mm

- ER 90 mm x 63 mm

- ER 90 mm x 75 mm

- ER 110 mm x 63 mm

- ER 110 mm x 75 mm

- ER 110 mm x 90 mm

TEE REDUCER

Sizes

-

- ETR 25 mm x 20 mm

- ETR 32 mm x 20 mm

- ETR 32 mm x 25 mm

- ETR 40 mm x 20 mm

- ETR 40 mm x 25 mm

- ETR 40 mm x 32 mm

- ETR 50 mm x 20 mm

- ETR 50 mm x 25 mm

- ETR 50 mm x 32 mm

- ETR 50 mm x 40 mm

- ETR 63 mm x 20 mm

- ETR 63 mm x 25 mm

- ETR 63 mm x 32 mm

- ETR 63 mm x 40 mm

- ETR 63 mm x 50 mm

- ETR 75 mm x 32 mm

- ETR 75 mm x 40 mm

- ETR 75 mm x 50 mm

- ETR 75 mm x 63 mm

- ETR 90 mm x 40 mm

- ETR 90 mm x 50 mm

- ETR 90 mm x 63 mm

- ETR 90 mm x 75 mm

- ETR 110 mm x 50 mm

- ETR 110 mm x 63 mm

- ETR 110 mm x 75 mm

PPR PIPE CUTTER

Sizes

-

- EPC 20 to 32

- EPC 20 to 63

- EPC 75 to 110

PPR PIPE CUTTER

Sizes

-

- EPC 20 to 32

- EPC 20 to 63

- EPC 75 to 110

Contact us today

We can provide you high quality products from PVC Pipe, Polycarbonate Sheet to Era PPR, and more. Our prices are competitive and we serve our clients with excellence.