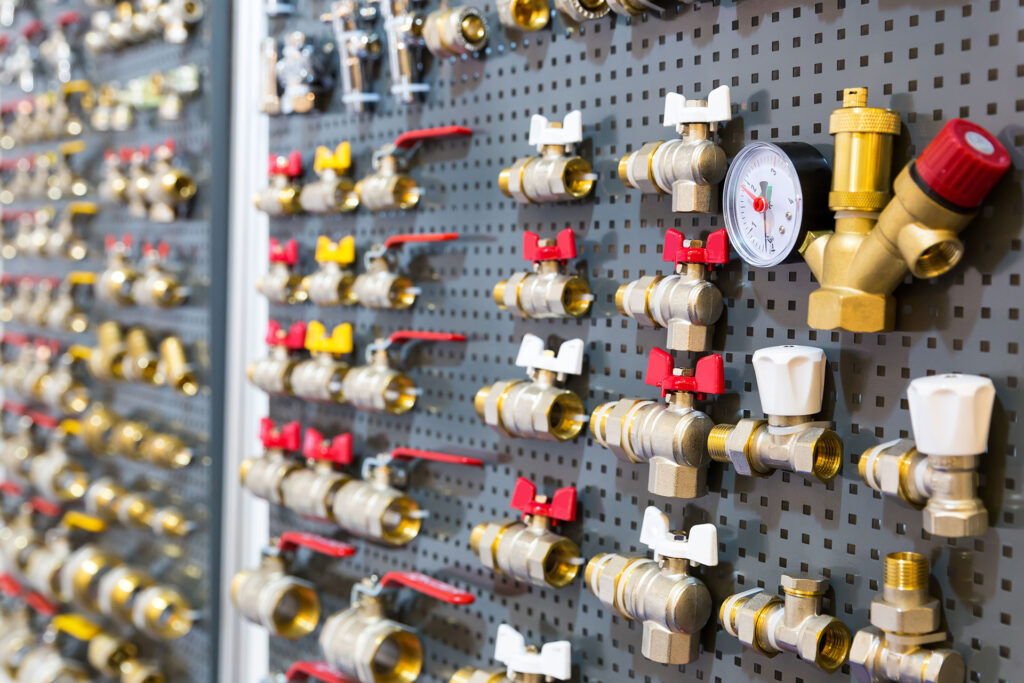

10 Jun 5 Factors to Consider When Choosing the Right Valves

Valves are essential for every plumbing system because they control, regulate, and direct the flow of fluids as well as gas that pass through the pipes. Given the many valve options available, it can still be difficult to find the right one if you don’t know how to determine the significant features needed to assure that the valves will match with the application you are going to use it for. That’s why in this article, we will be listing down the factors to consider when choosing the right valves.

1. The Functionality of the Valve

Look for a type of valve that is able to perform at least some of these basic functions: pressure relief, backflow prevention, adjust flow, shutoff flow, divert flow, and mix flow. Checking the functionality of the type of valve before proceeding to choose or buy it will be helpful in determining the type of valve that’s ideal for your need.

If you want to have on/off control for your system, go for 2-way valves because they have an inlet and outlet where the fluid can properly enter and leave the port. 3-way valves on the other hand, allow the mix of liquids from two different pipes into one pipe or separate water from one pipe into two different pipes because they have 3 ports. Usually, these ports consist of 1 inlet and 2 outlets or 2 inlets and 1 outlet, which can be used to close the port and stop the water flow in one pipe while letting liquid or gas content flow in another pipe.

2. Size and Type of Valve

Next to the functionality are the size and type of valve. These two should always go together because the sizing will depend on the type of valve you will choose. When the type of valve and sizing matches, it will result in better performance and flow in the piping system.

3. Valve Requirements

Checking the requirements is another factor to consider when choosing the right valves. See to it that the valve is properly working and is able to meet certain requirements such as its response time and ability to control or regulate pressure that’s needed to open a valve. It is also important to take into consideration whether the valve will usually be open or closed as well as the pressure and temperature ranges that it can handle.

4. Material Used to Make the Valve

Take note that the materials used to make the valve should fit the liquid or gas content that’s going to flow through it. Compatibility is necessary to assure long-term operation, better handling of pressure, and processing of contents. In the event that harsh chemicals will flow through the valves, opt for plastic valves because they are more resistant to chemicals compared to metal valves.

5. Maintenance of the Valve

Regular maintenance is mandatory to ensure the lifespan and stability of the valves. Pay attention to the type of valve you will choose and what can help avoid damage or more costly repairs.

In need of affordable and high-quality uPVC valves, PVC pipes, and fittings for your next project? Inquire from us today and we will offer you high-quality products that you’ll need for your project.

Don’t forget to like and follow us on our Facebook page!